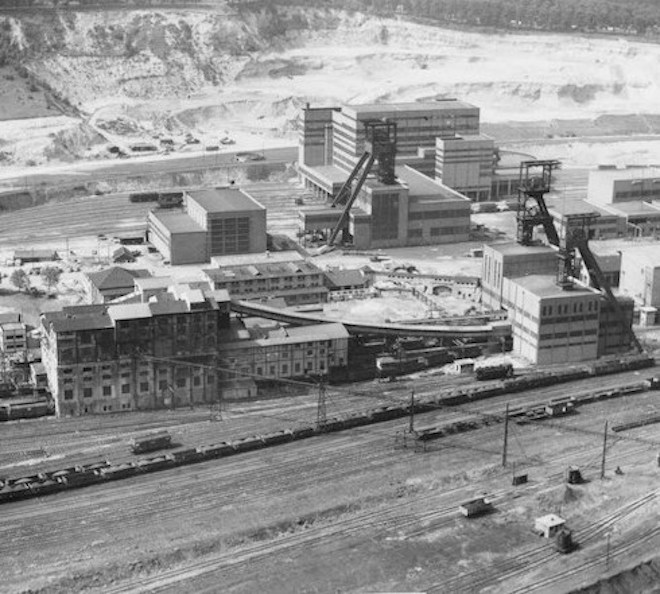

COAL WASHING PLANT #3 [FR]

Exploration #108. Initially discovered in Saarland, the Sarrois-Lorrain coalfield was extracted on the French side in Petite-Rosselle from 1856. The site was under concession to the De Wendel family, then head of the French iron and steel empire.

The excavation of the Wendel well no. 1 began in 1865 and was completed three years later. The excavation of Wendel well no. 2 began the same year near Urselsbrunn and was completed in October 1871. In 1935, the discovery of a deep and rich coal deposit started the excavation of Wendel Well No. 3, which was completed in 1947 at a depth of 900m. In 1960, the Wendel mine could extract up to 10,000 tons of coal a day with a workforce of 5,000 miners.

The Wendel 1, 2 and 3 wells ceased operation in 1989 while some of the plants continued to be used until they were finally closed down in May 1991. Most of the mine and wells 1 and 2 have been rehabilitated and turned into a museum, while well 3 and the connected plants are still abandoned.

These photos refer to the washing plant connected to well 3. The Wendel wash-house 3 was at the forefront of modernity. It was able to carry out all the operations of sorting, screening, crushing, separation, grading and storage for a production of 5000 tons of coal per day. Simply put, the role of the washing plant is to prepare the raw coal for marketing. The main operation is to separate the coal from the waste rock (shale). To do this, the washing plant 3 has been equipped with several Wemco washing bins for dense liquids. The raw coal was fed into these drums containing a suspension of magnetite in water. The (less dense) coal floated, while the shale was recovered at the bottom. The shale (coal dust) was then treated in a flotation plant. After the addition of a surfactant, the slime suspended in water was remixed in small tanks. The coal dust, which is hydrophobic, rose to the surface in the form of foam, collected by scrapers.